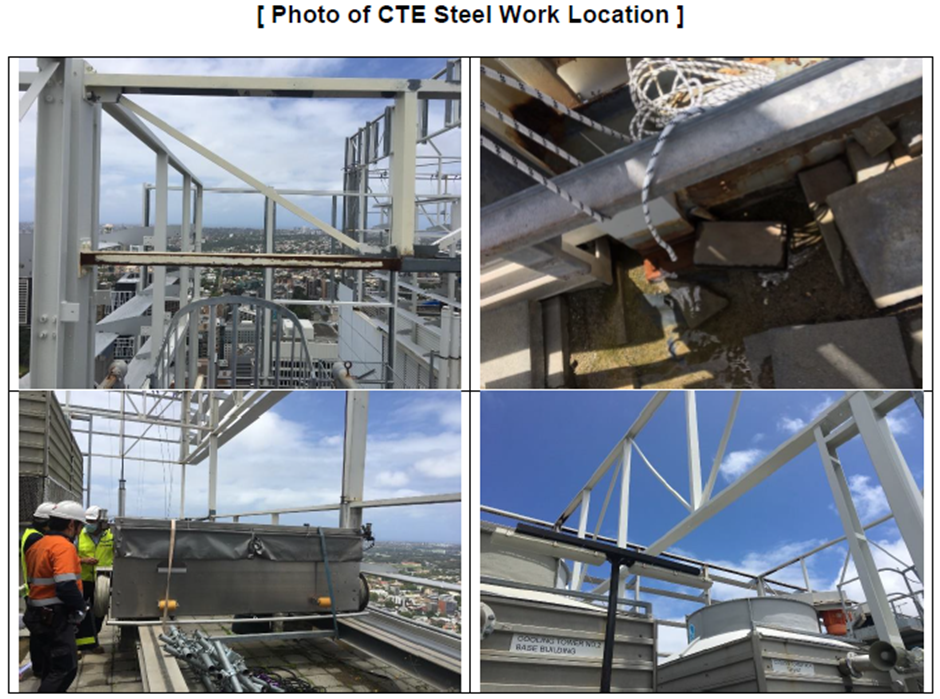

WORLD SQUARE_CTE STEEL WORKS

Location 680 George St Sydney NSW 2000

Job Title World Square CTE Steel works Project

Service Welding and Fabrication/ Equipment and tool supply

Scope of Work

(Work Scope Summary)

| Item# | Work Description | Weight Value | Location | Note |

| 1 | Weld repair | 50% | TBA | N/A |

| 2 | Fin Plate | 30% | TBA | N/A |

| 3 | Structure | 20% | TBA | N/A |

| Total | 100% |

Project Resourcing

Workshop personnel included Coded Welders and Boilermakers. The support team included Project Management, Quality Management, Project Engineer and Project Supervisor.

Methodology (Work Sequence)

1. Obtain the correct permit for Hot-works (Welding / Grinding)

2. Obtain the correct permit for Work in Heights (Harness)

3. Obtain the correct permit for BMU Operation

4. Pre-start BMU before use

5. Set up the Power distribution board (lifeguard 32amps) if required

6. Check the “Inspection report” to confirm the location / Process required

7. NDT (V.T) on the Steel surface and Surface preparation by Grinder

8. Cut out the OLD section / Measuring and cut NEW to the size

9. Cover up the area with Monarflex sheet around (If required)

10. Set up the Welding Equipment / Welding Consumables ready

11. Wind Speed Anemometer ready (calibrated)

12. Fit up the new piece and Fit-up check by inspector If required

13. Carry out the welding with Approved WPS (MMAW)

13a. Back-step welding technique to prevent Distortion (excessive heat input)

13a-1. Amps x Volts x 0.06 divided by Travel Speed (in/minute)

13b. Do not start if winds over 20km / h (TA needs to check constantly and record)

13c. Check the thickness of material to achieve the Weld Throat as required

14. Carry out the NDE testing after cool down

15. Clean up the area and disconnect all the Power

16. Move to the next location

17. Variation

Documents Supplied/ Training completed

- WPS & PQR

- Crew Qualification

- WMS (Work Method Statement)

- SWMS

- Work Progress Report (Daily basis)

- Online Induction, Site Induction, BMU Training and Working at height

Health and Safety Summary

(Health, Safety and Environment Performance (Inc. Subcontractors))

| No. | Description | Cumulative |

| 1 | SAFETY INTERACTION | N/A |

| 2 | SCAFFOLDING | N/A |

| 3 | TEST AND TAG, RIGGING INSPECTION | N/A |

| 4 | WORKING AT HEIGHT (HARNESS) | WAH Check |

| 5 | BMU OPERATION | N/A |

| 6 | TOOL LANYARDS AND STRAP | N/A |

Project Achievements

We’ve proudly completed the project with high standard performance on schedule.

All procedures were qualified and approved by International and Australian standards prior to the project commencement:

- Zero (0) Lost Time Incident, Zero NCR during the project

- Zero failure rate on overall welding

- Project delivered on time and under budget

- Protech Welding Pty Ltd worked closely with the client nominated site supervisor to ensure all project quality requirements were exceeded for the duration of the project

Activities

- Active interaction with our client to ensure quality of finished product/ services was in line with practical requirements, especially to set up the work methodology, BMU and weather protection for power sourced equipment at preparation stage.

- Be compliant with site rules/ Health and safety requirements e.g. Thorough Wind Speed Inspection to obtain work permit before start work

- Project and quality management

- Constant communication with our client through work progress report on a daily basis

Work Photos